TEP’s first utility-scale solar array began taking shape around the turn of the 21st century in the high desert grasslands near our coal-fired Springerville Generating Station (SGS). By 2004, it had been expanded to a capacity of 3.7 megawatts (MW) – making it, for a time, the most productive grid-tied solar array in the Western Hemisphere.

The system was expanded twice in 2010, and the White Mountain solar array was added alongside it in 2014; the systems can now generate a combined 13.5 MW. Last year, they produced enough clean energy to serve the annual electric needs of nearly 1,800 average Tucson homes.

From the beginning, maintenance of these solar arrays was outsourced to local contractors. Last year, when our main contractor announced he would retire this June, our SGS team decided to bring the maintenance in-house, given the scarcity of other vendors in the area.

“When this idea was presented last fall, employees really took ownership of this project,” said Maintenance Superintendent Kenny Blank, who is overseeing the transition. “We all see the need and opportunity to give our employees new knowledge and skills in renewable energy.”

Springerville teams have been gearing up to assume maintenance of the solar arrays by shadowing the contractor and integrating plans and work processes into our internal systems. They’ve also received expert guidance and assistance from the TEP asset manager who oversees all of our company-owned solar power systems.

“The great thing about this transition is that different elements of the process and maintenance fall into different areas to help manage the work efficiently,” Blank said. “Our planners help us secure parts, the electricians perform testing and checks, and our engineers assist with designing or retrofitting these systems.”

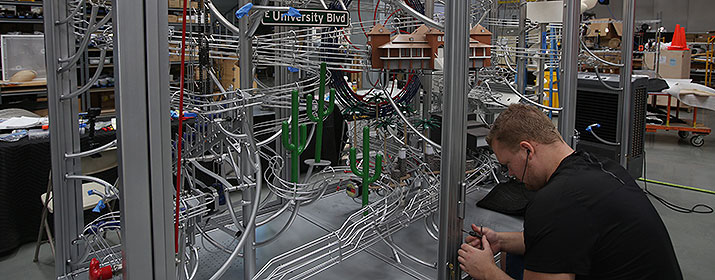

As technology has advanced, one challenge of maintaining an older system is that some of the parts and equipment are no longer available. Employees may need to repair or retrofit existing parts or fabricate new parts with engineering support. “We have a lot of smart people at the plant who can leverage their talents and creative thinking to find solutions and preserve our investment,” he added.

Maintaining the solar arrays on site gives employees additional skills in the growing renewable energy industry. It also saves money by reducing the need for Tucson-based employees to travel to Springerville. The solar panels will be TEP’s only generating resource in the area once our two coal-fired units at SGS are retired in 2027 and 2032.

Dylan Bearce, Senior Director of Energy Resources, said the teamwork demonstrates how employees are living out our corporate values.

“As a company, we strive to create a collaborative, inclusive culture where each of us feels empowered to contribute and leverage our unique skills and talents to meet any challenge we face,” he said. “We are better working together. We also know investing in our employees through continuous learning will help us achieve operational excellence.”